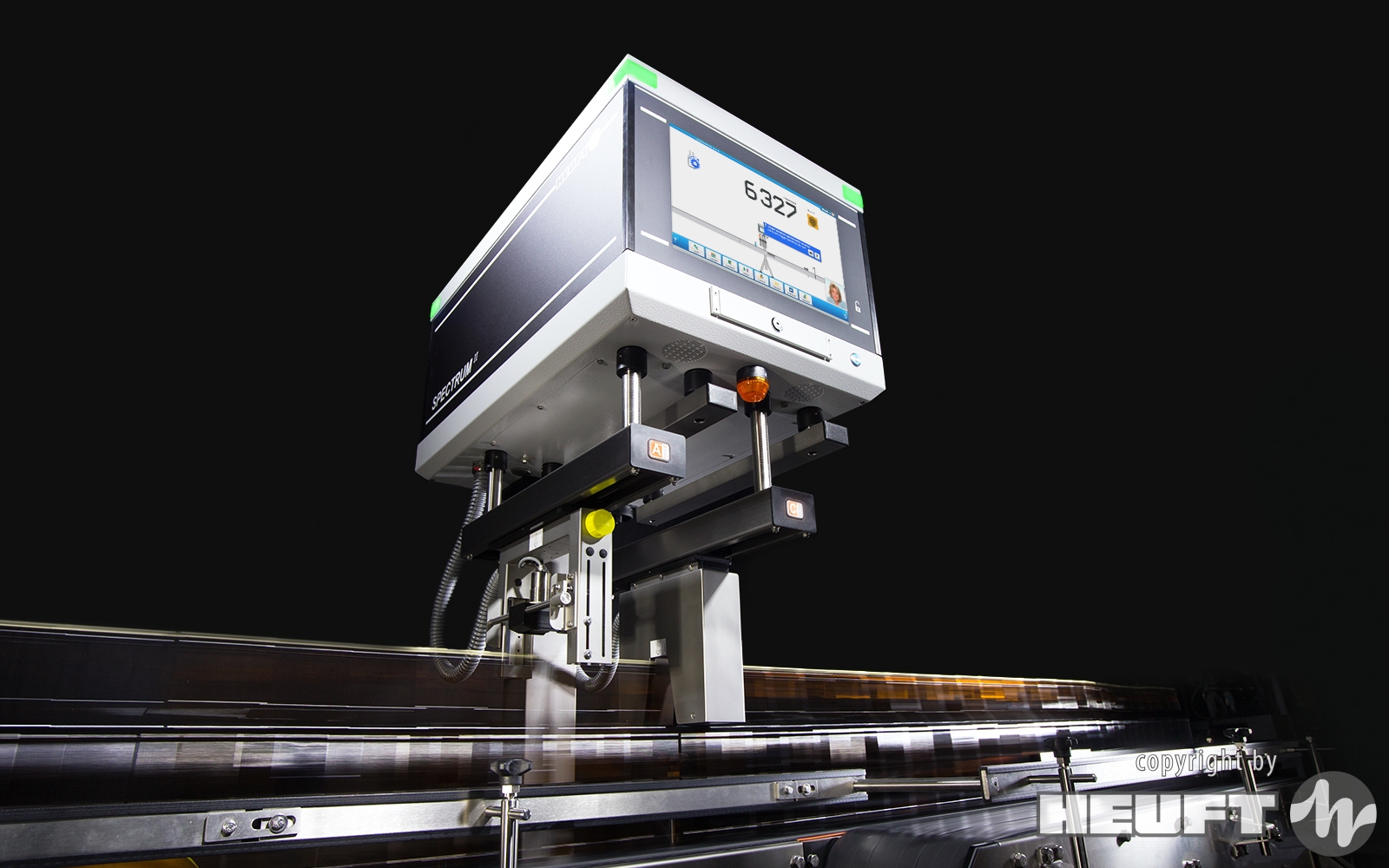

Highly automated, universal and powerful: the HEUFT SPECTRUM II ensures optimum detection and operational reliability during an in-line inspection for the sustainable safeguarding of product quality and line efficiency.

The cross-system control unit with multiprocessing capability for different modules, systems and applications convinces due to its exceptional degree of automation. Brand and format changes can be carried out without manual intervention. The unique human machine interface of the universal device platform is self-explanatory. Human resources are effectively saved in this way. In-house developed hardware and software of the latest generation and a future-proof network connection achieve highest computing power and data transmission in real time. The result: maximum precision during purposeful product tracking, inspection and rejection.

The functions of the HEUFT eXaminer II XOS:

• X-ray base inspection: Flashing instead of X-raying: maximum detection performance and minimum emission.

• Optical base inspection: Looking closely: special optics for difficult cases.

• 360° sidewall inspection: Not overlooking anything: safe all around due to optical all-around inspection.

• Fault rejection: Preventing recalls: the reliable rejection of faulty containers.

• Product monitoring and self-tests: Playing it safe: exact product tracking and regular self-tests.

• Optional additional functions: Detecting even more: extensions to the range of functions.