12.5% increased production capacity & 90% savings on labor costs by filling machine with robot

This filling machine with robot was specially developed for a customer who needed to improve their production process. The goal was to automate the process of handling 25kg bags in order to increase productivity and reduce labor costs. In the process, the empty bags must be picked up, after which they must be accurately filled. After the bags have been filled, they must be sealed and stacked on a pallet.

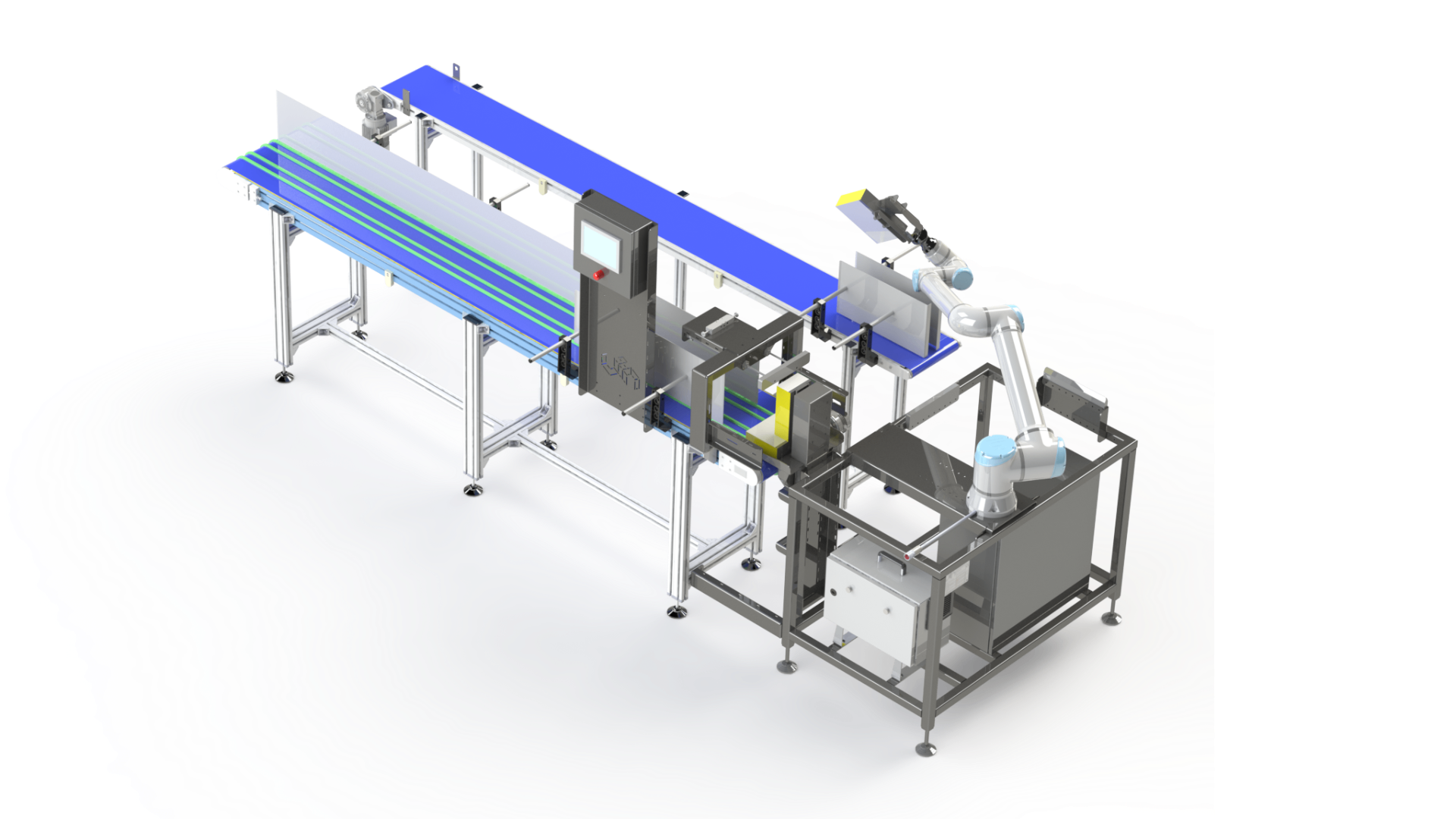

In order to meet the customer’s wishes, we created a setup under the customer’s silo. We used a robot with a multifunctional gripper on a stainless steel frame, a table where the empty bags can be placed, a conveyor belt, a push-out container and weighing modules that accurately weigh the weight of the bags.

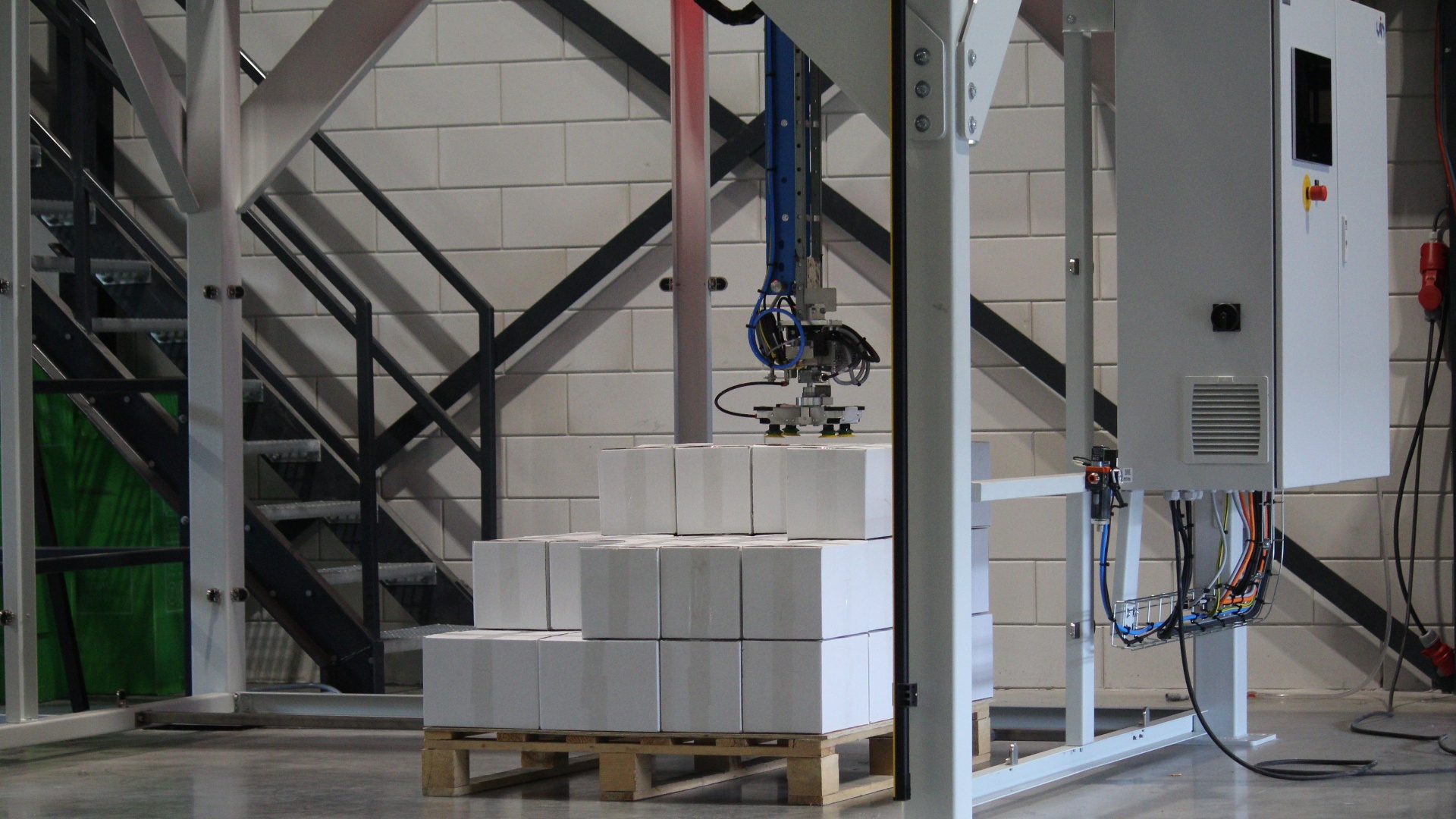

Two tubes with filling mouths are connected under the silo. The operator ensures that a pallet is in the right place and that there are empty bags on the table. The robot arm picks up the empty bag with a small gripper with slides and slides it over the filling mouth. The bag that is being filled in the meantime is on a container that weighs the bag accurately by means of a weighing module. At 25 kg the machine stops filling and the bag is sealed shut by means of heat bars. The push-out container in which the bag is placed slides the bag onto the conveyor belt, after which it is transported to the end of the conveyor belt. The robot picks up the bag from the conveyor belt with the large vacuum gripper and places it on the pallet. The filling mouth, the weighing modules and the push-out containers are double, which ensures that the process runs smoothly. The process is repeated until the pallet is full.